Testing RFC 2544 and GameChanger

The document identifying the test parameters from IETF (Internet Engineering Task Force) is designed to stop what they call “specmanship” from vendors to give themselves a better position in the marketplace, as they feel this practice often involves smoke and mirrors to confuse the potential users of a product. The tests are available for vendors to use and will provide users with test results in an apples to apples (device to device) fashion in a comparable comparison format. In this case, the DUT (Devices Under Test) are a pair of Viavi TBERG 5800 testers. The media over which the tests are run is the GameChanger cable. Connections are made from transmit of one device to receive on the other.

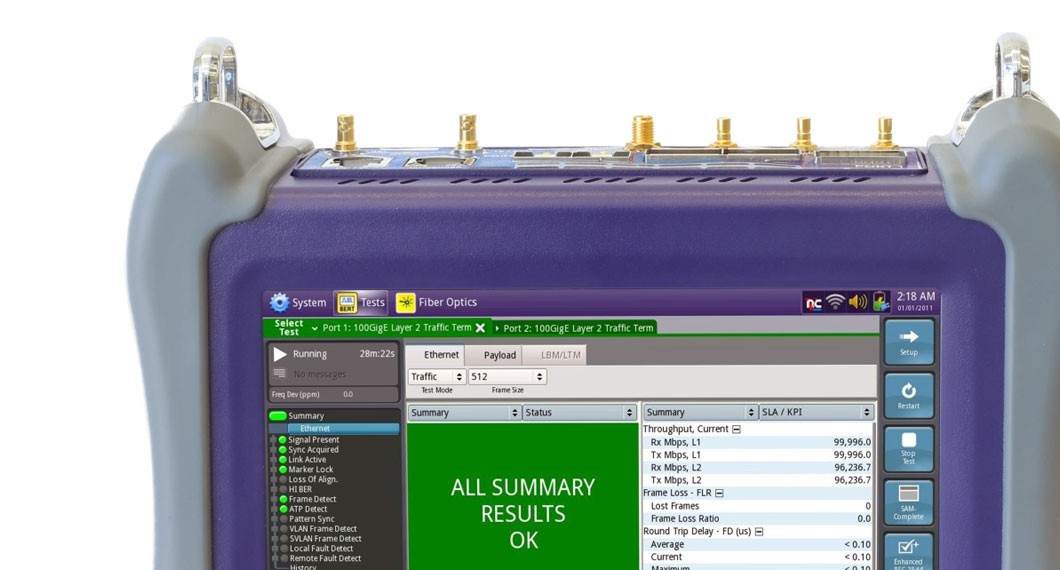

In the testing scenario, the DUT (Device Under Test) is connected to send and receive ports on a tester. Send of the DUT is connected to the receive on the tester and the receive on the DUT is connected to the send port of the tester. The idea if the tests is to determine frame loss over the transmission, latency and other parameters. This test differs from some of the other Ethernet tests in that it can be used both on the Local Area Network and over carrier Ethernet WAN links. This allows testing of a variety of equipment which can be placed inline between testers and can certify the performance for extended demarcations and other latency sensitive equipment. The question of testing arrised over just such a query where additional devices made it very difficult to determine where the slowdown occurred and which equipment was at fault.

The tests performed are done so with a variety of frame sizes, or at the least, the minimum and maximum frame sizes that are used in the protocol under test on the media under test and enough in between sizes to get a full characterization. The recommendation from the IETF is that at least 5 frame sizes be used. For Ethernet, the recommended frame sizes are 64, 128, 256, 512, 1024, 1280 and 1518 bits. Frames such as keep alive frames and routing update frames should be discarded in the test.

The Viavi testers offer complete TIA 568 and ISO 11801 copper and fiber certification along with the RFC testing mentioned. This adds Viavi to our list of test manufacturers that can test and certify GameChanger cable prior to the active equipment being added to the channel. This also means that the cables can be tested as part of extended demarcations and other latency sensitive uses prior to devices being added. The problems with introducing electronics, repeaters and other inline devices are risk, complexity, security, and in fact, these risks are so great that in some secure environment, they simply aren’t allowed. This means that additional IDFs/telecommunications areas must be defined and deployed at a far heftier price tag than a simple length optimized cable will cost in a deployment.

To view the test results, click here. For more information on GameChanger cable and other Paige DataCom products, please visit our webpage or contact your local Paige representative.