Water Intrusion in Cables: How to Keep Connections Dry and Reliable

When it comes to outdoor cable installations, the potential for water intrusion is a significant factor to consider. Whether you're connecting a camera to a building exterior or running cable through a conduit, exposure to moisture can compromise cable performance, shorten its lifespan, and, in some cases, lead to costly downtime. Fortunately, there are effective cable designs and protective measures to counter water intrusion and ensure dependable connections. In this post, we’ll dive into the two primary ways water can enter a cable and how to select the right solution to prevent it.

Water Intrusion at the Cable Termination Point

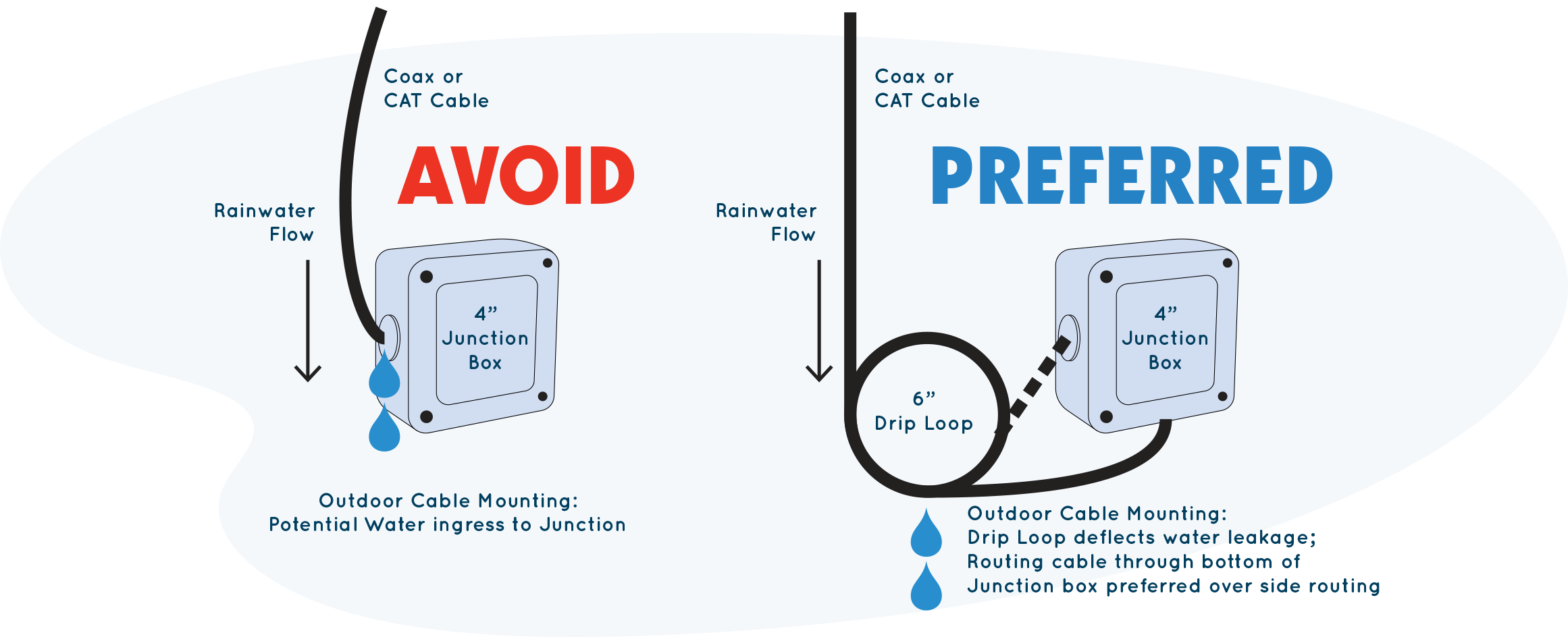

The first key area where water can penetrate a cable is at its exposed termination point. Imagine you're installing a security camera on an exterior wall—if rain or water spray reaches the cable end near the camera, there’s a risk that moisture will enter at that connection point and travel down the cable. For installations exposed to intense water sources, like driving rain or even hoses, this can quickly become a problem.

A proper drip loop is your first defense against water intrusion.

A proper drip loop is your first defense against water intrusion.

How We Design for This:

To prevent water from moving along the cable’s interior, we use a gel-filled core in our outdoor-rated cables. This gel acts as a barrier, blocking water from traveling further down the cable. Think of it as a safety net that stops moisture in its tracks, maintaining signal quality and extending the cable’s lifespan. If your installation is in a lower-risk location—where water exposure is minimal—then using a wet-rated connector and incorporating a drip loop may provide sufficient protection. This setup allows water to flow away from the termination point, reducing the risk of moisture entry without needing a gel-filled core.

Water Intrusion Through Conduit Wear and Tear

The second way water can infiltrate a cable is through the conduit. Cables pulled through conduit may encounter rough sections, which can create small holes or abrasions in the outer jacket. If water fills the conduit due to rain or flooding, it can seep into the cable through these minor breaches.

How We Address This:

For environments where cables are pulled through conduits, a gel-filled core offers an extra layer of security. Gel-based water blocking is highly effective in this scenario. Compared to dry tape, which can tear under friction, gel provides robust resistance to water intrusion even if the jacket sustains minor damage. Additionally, using a jacket material like FEP (commonly known as Teflon) in our Indoor/Outdoor Plenum-rated cables further reduces the risk of tearing during conduit installation. FEP jackets are more durable, flexible, and resistant to punctures, making them ideal for conduit applications where wet conditions may arise.

Choosing the Right Cable for Your Environment

When selecting a cable for installations where water exposure is a concern, consider both the type of exposure and the environment. For areas with limited water exposure, such as indoor/outdoor installations protected from direct rain or water spray, our Indoor/Outdoor Plenum-rated cable with an FEP jacket is a great choice. Its robust design reduces the chance of jacket punctures, making it suitable for conduit use where minimal water contact is expected.

However, if the installation site is exposed to intense water sources, like high-pressure hoses or frequent heavy rain, using a gel-filled OSP (Outside Plant) cable with a water-blocking core is your best bet. This solution provides the highest level of protection, ensuring that even in challenging conditions, your connection remains intact and reliable.

In summary, understanding the two primary ways water can enter a cable—through the termination point and the conduit—helps guide cable selection and installation practices. By using the appropriate cable design for your specific environment, you can achieve the reliability you need without the risk of water intrusion affecting your connections.